Work clamps are a fundamental part of what – As work clamps take center stage, this discourse embarks on an in-depth exploration of their fundamental role in a myriad of industries, unraveling their significance in enhancing safety, precision, and productivity.

From construction sites to manufacturing plants, automotive repair shops to woodworking studios, and DIY projects to specialized sectors, work clamps stand as indispensable tools, shaping the very essence of these domains.

Work Clamps: A Fundamental Tool in Various Industries: Work Clamps Are A Fundamental Part Of What

Work clamps are an indispensable part of countless industries, providing a secure and efficient means of holding and securing workpieces during various tasks. From construction to manufacturing, automotive repair to woodworking, work clamps play a pivotal role in enhancing safety, precision, and productivity.

1. Work Clamps in Construction

In construction, work clamps are extensively used to secure and align building components, ensuring stability and accuracy during assembly. They are commonly employed for tasks such as framing, roofing, and cabinetry, where precise alignment and secure hold are crucial for structural integrity.

2. Work Clamps in Manufacturing

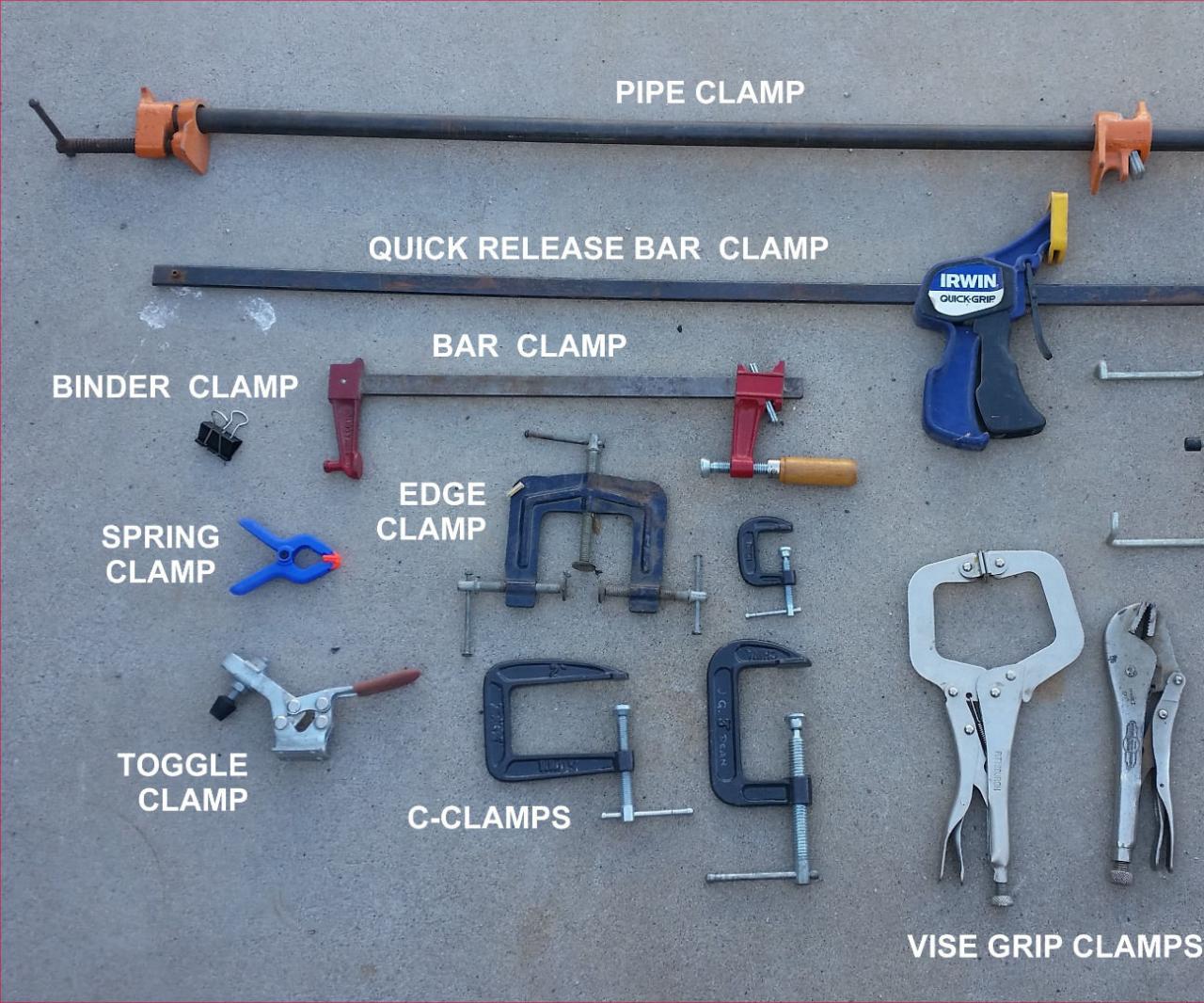

In manufacturing, work clamps are vital for holding workpieces in place during machining, welding, and assembly processes. They ensure precise alignment and stability, minimizing errors and enhancing productivity. Common types of work clamps used in manufacturing include C-clamps, toggle clamps, and vise clamps.

3. Work Clamps in Automotive Repair, Work clamps are a fundamental part of what

Work clamps are essential in automotive repair shops for holding components in place during maintenance and repairs. They are used to secure body panels, align engine parts, and provide stability during welding and assembly tasks. Proper alignment and stability are crucial for ensuring the proper functioning of vehicles.

4. Work Clamps in Woodworking

In woodworking, work clamps are indispensable for holding workpieces together during gluing, assembly, and shaping operations. They prevent warping, ensure alignment, and provide stability, resulting in precise and durable finished products. Common types of work clamps used in woodworking include bar clamps, pipe clamps, and quick-release clamps.

5. Work Clamps in DIY Projects

Work clamps are versatile tools for DIY enthusiasts, enabling them to undertake projects with greater confidence and success. They are suitable for a wide range of tasks, including woodworking, home repairs, and crafting. Easy-to-use and adjustable, work clamps provide a secure hold and stability for various materials.

6. Work Clamps in Other Industries

Beyond the aforementioned industries, work clamps play a crucial role in various other sectors, including aerospace, shipbuilding, and metalworking. They are essential for holding and securing components during fabrication, assembly, and repair processes, ensuring accuracy and efficiency.

FAQ Insights

What are the different types of work clamps?

Work clamps come in various forms, including C-clamps, bar clamps, quick-release clamps, spring clamps, and specialty clamps designed for specific applications.

How do work clamps enhance safety in the workplace?

Work clamps provide a secure hold on workpieces, preventing them from slipping or moving unexpectedly, thereby reducing the risk of accidents and injuries.

What are the benefits of using work clamps in woodworking?

Work clamps in woodworking ensure precise alignment, prevent warping, and maintain the stability of workpieces, leading to superior results and reduced waste.